Date

2018/02/20

Soil Quality ebook

Soil Quality: 2 Integrated Soil Management

Organisations

SoilsWest

Department of Primary Industries and Regional Development

Grains Research and Development Corporation

Authors

Wayne Pluske

Guy Boggs

Matthias Leopold

A panel of experienced consultants give their insights and suggest management on a range of example profiles from across the southwest agricultural region of WA, along with expert technical advice from Department of Primary Industries and Regional Development scientists.

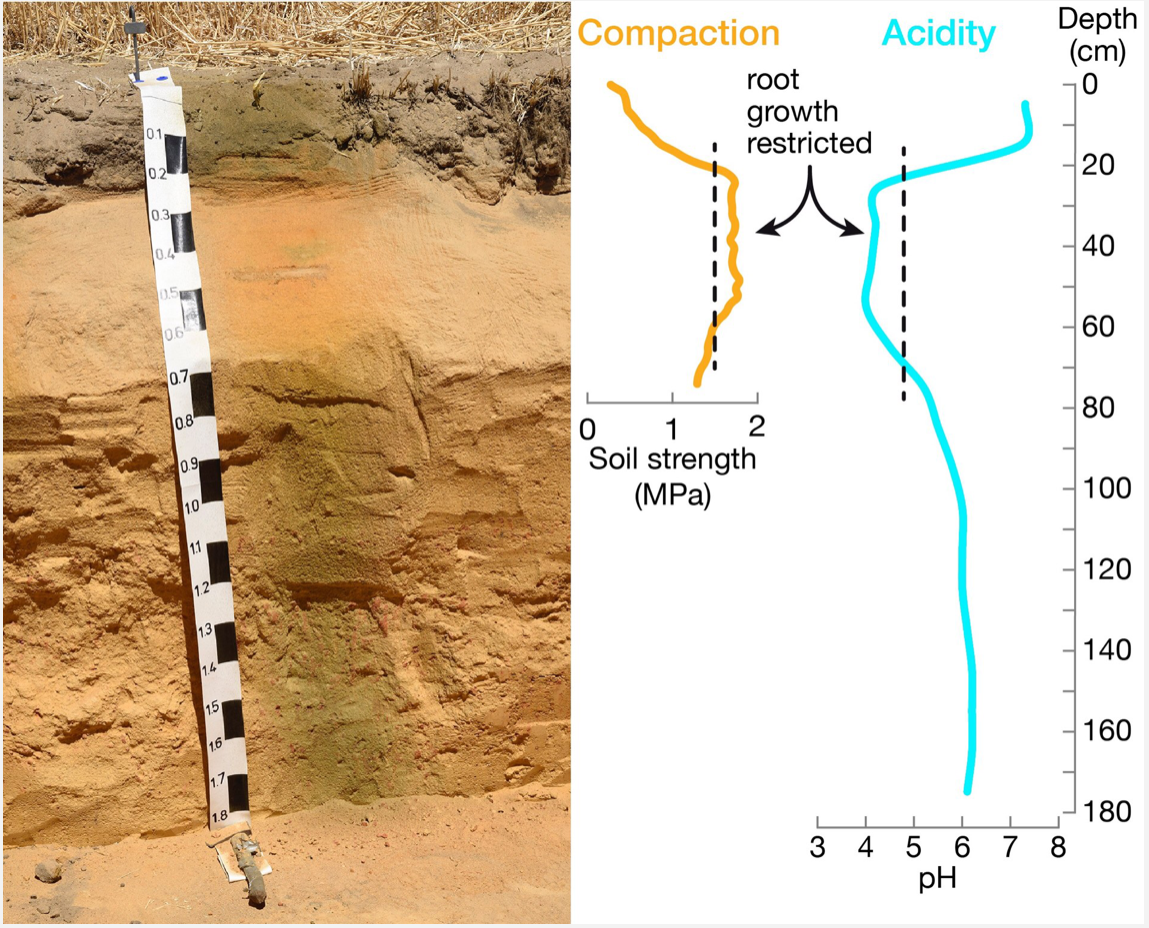

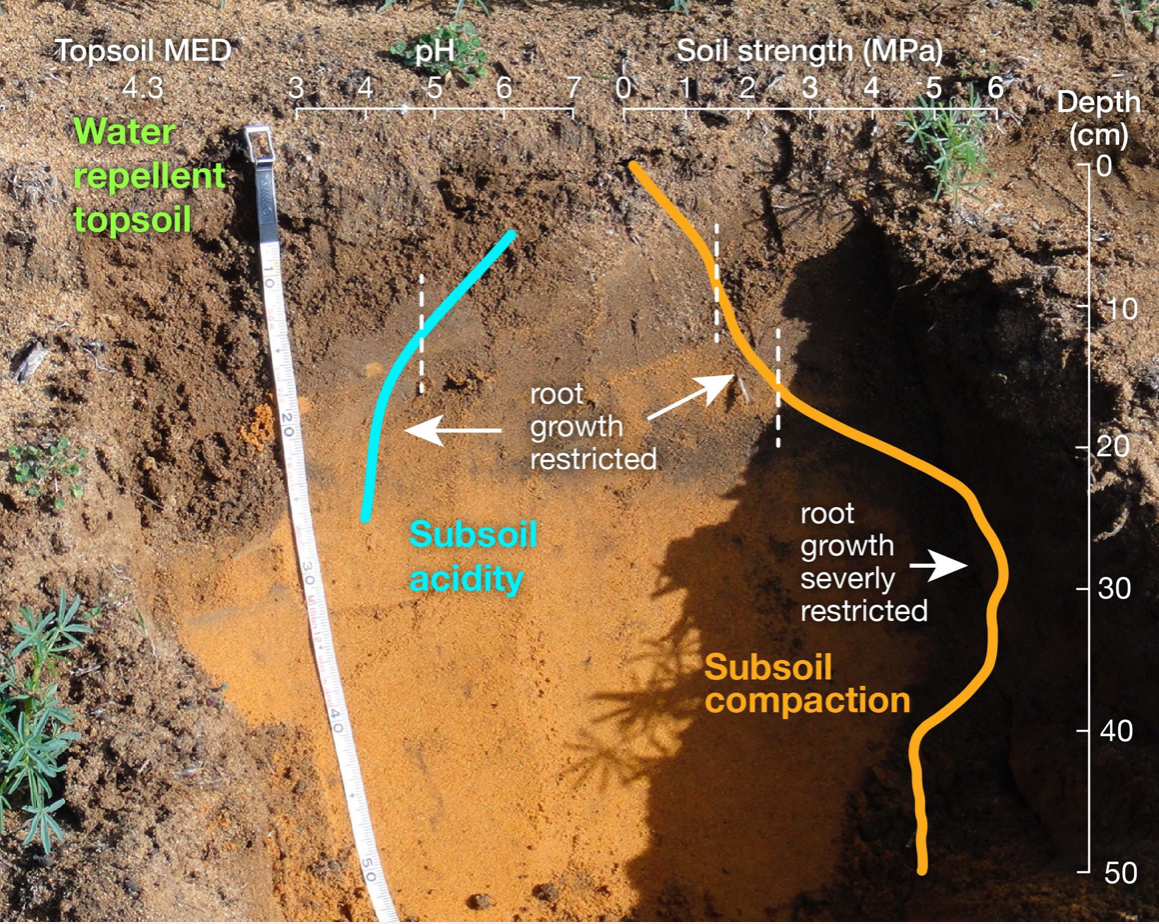

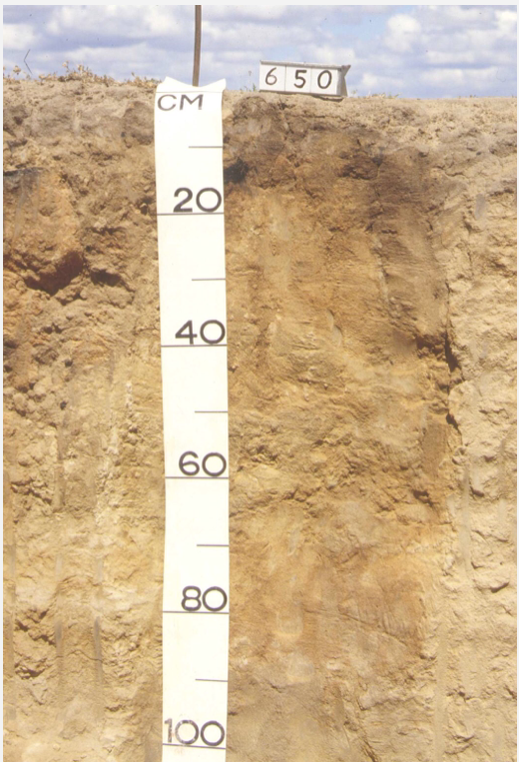

This soil profile highlights the importance of testing the subsurface soil. A topsoil pH of 7.3 is uncommonly good, however acidic subsurface is common and goes undetected unless pH is tested down the profile. The acidic subsurface layer inhibits growth of roots (both speed and depth) down to valuable moisture and nutrients, especially later in the growing season. In these yellow sandplain soils, in the absence of constraints, wheat roots can grow down 2.5–3 metres.

An ongoing liming regime combined with deep ripping beyond 30 cm with topsoil slotting can fix the key constraints in this soil. This soil is ideal for topsoil slotting because its surface pH is already high. The organic-rich, high pH soil can fall through inclusion plates down to 50 to 60 cm, both diluting subsurface acidity and enabling any remaining ‘free’ lime near the soil surface to neutralise subsurface acidity. Simply applying lime to the topsoil before slotting will not have the same effect on acidity because insufficient lime and higher pH soil will end up down the profile.

It is important to plan where and when paddocks will be limed, deep ripped and/or slotted. High topsoil pH soils are ideal for ripping and slotting first while implementing a liming program to raise the topsoil pH of other paddocks.

Most farmers with yellow sandplain soil have rippers that can be fitted with inclusion plates that should get topsoil down to at least 30 cm, so if ripping down to 60–70 cm isn’t currently possible, it is worth starting with slotting to 30 cm.

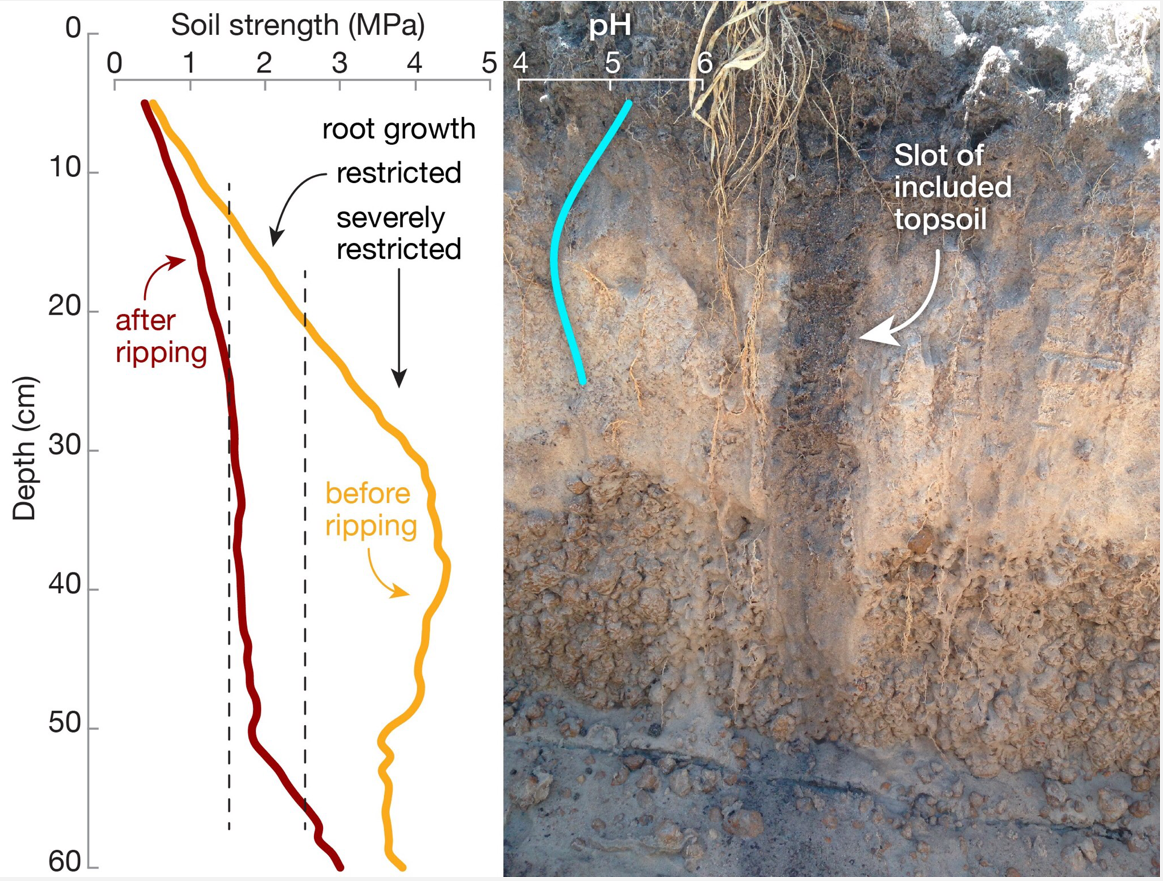

In compacted soil, the indications are that the response in wheat to ripping to 30 cm will be 400–500 kg/ha compared to a 600–800 kg/ha response to ripping to 60 cm. With this scenario, a $120 000–$140 000 machine capable of ripping to 60 cm is an attractive investment option.

To gauge the extent of soil compaction it is a good idea to test many sites across a paddock after rain has wet up the soil profile by pushing a steel rod with a bar fitted across the top into the soil (homemade penetrometer). While this can’t quantify the exact strength of the soil in a compacted layer, it can provide an indication of what parts of the paddock are most compacted and at what depths. This information, together with soil pH test results, can help to assess where your best responses from ripping and/or liming are likely to be.

If you are making a significant investment in deep ripping these soils it is important to protect this investment long-term by moving towards controlled traffic farming to line up as many wheel tracks as possible to minimise recompaction from machinery. Even with controlled traffic farming, the soil may recompact itself and deep ripping will again be required. The timeframe for this ‘strategic’ tillage is uncertain at this stage but is probably 5–10 years.

The immediate challenge with water repellent soil is getting plants to establish. Seeding wet with good press wheels is usually the best option. There can be benefits from paired row seeding systems, which can place seed into firm soil in the shoulders of the furrow, grade repellent soil out of the furrow and reduce intra-row competition. Sowing on or near the previous year’s crop row is often effective with the previous year’s crop crowns and roots acting as preferred pathways for early rain events. Although results with “wetting agents are inconsistent in these deep sands, they tend to be more useful and profitable when dry seeding moderate to severely repellent soils.

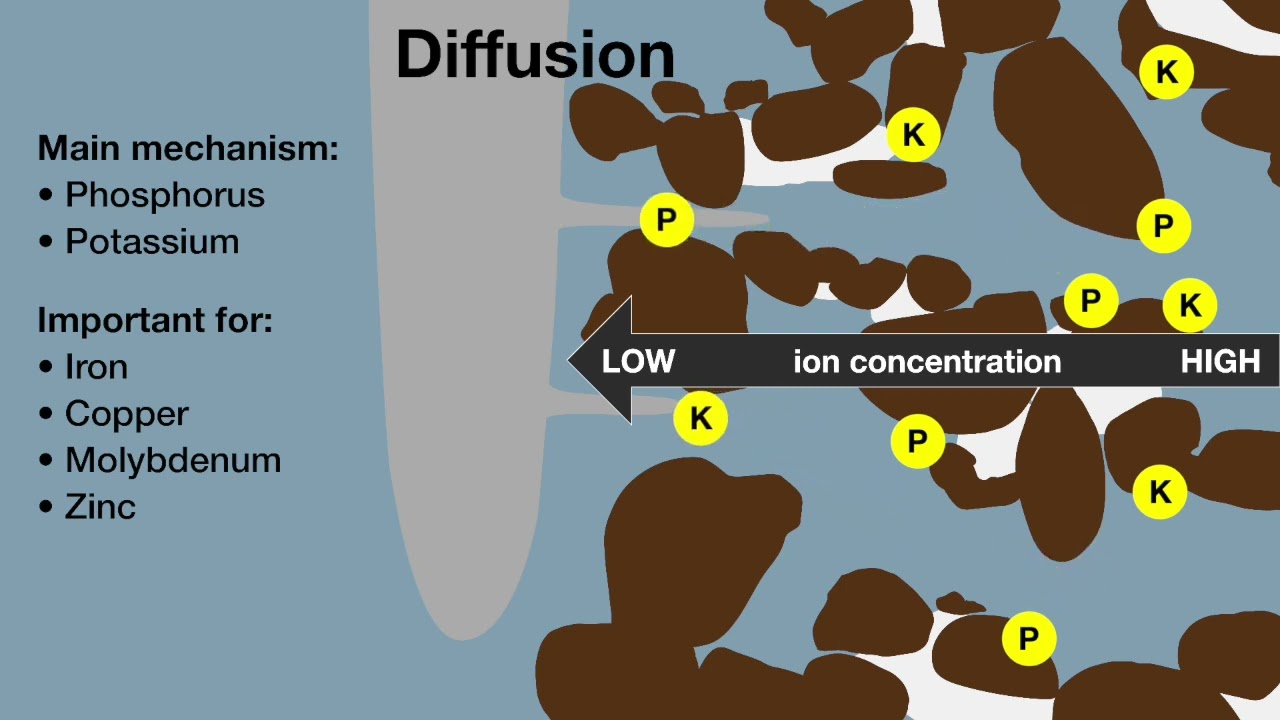

Ploughing to 30 cm (e.g. Grizzly or Plozza plough), mouldboard ploughing, and sometimes ripping with inclusion plates can help to ameliorate water repellent soil. Before going ahead with any longer term amelioration of this soil, it is important to know more about it. For instance, it is worthwhile knowing the pH below 30 cm and the fertility, especially potassium, of the subsoil. If the subsurface contains good reserves of nutrients, enabling roots to access it by investing in amelioration is likely to deliver additional yield with a less than proportionate increase in fertiliser expenditure.

Even with the good topsoil pH in this scenario, movement of lime through the profile in a minimum till system is slow so incorporation of lime and less acidic topsoil is important. Without mechanical incorporation, it would take at least five years before the soil pH at 30 cm depth is improved. Ripping with topsoil slotting is likely to be the best compromise in this case to integrate management of water repellence, subsoil acidity and subsoil compaction.

Many profiles similar to this scenario have been mouldboard ploughed over the last 3–5 years, prior to topsoil slotting with extra deep ripping becoming more common. The mouldboarding was done primarily for treatment of water repellence and weed control. However because mouldboarding only works to about 30 cm it cannot treat the compaction in this profile, which is typical of yellow sands worked by big machinery. To treat the compaction layer, ripping, perhaps to 80 cm in some cases, is required.

If this soil were ploughed with a mouldboard, the profile could be turned upside down depending on plough setup and operation. The surface soil pH would then be closer to 4 and the nutrient rich topsoil would be at depth—which is likely to be a better place for roots to access nutrients compared to the non-wetting surface. You would need to apply 2–3 t/ha of lime the following summer to address the topsoil acidity and a year or two after that you would still need to deep rip with topsoil slotting. Recovering a soil profile by this method is very effective but it is a 3–4 year project.

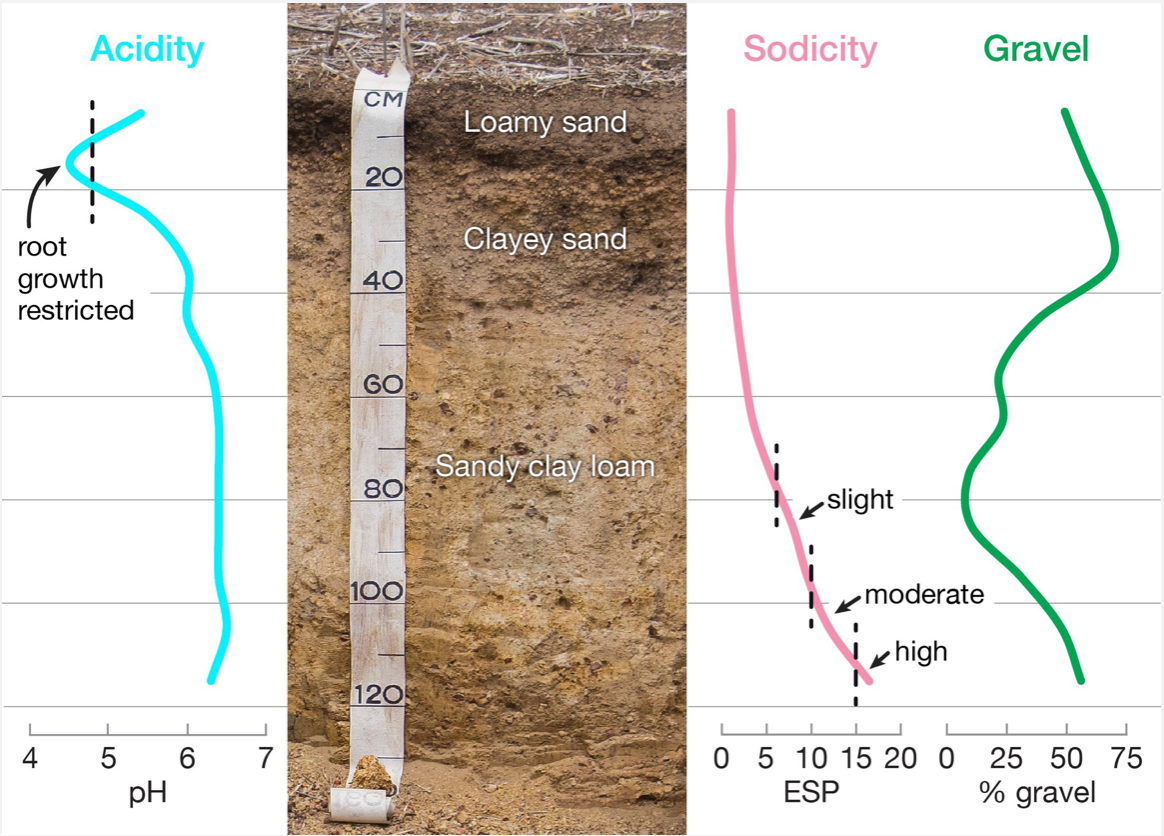

These can be challenging and nutrient hungry soil types, exacerbated by the fact that many gravel soils are in frost-prone areas and can harbour high levels of nematodes. Any investment in soil amelioration, especially capital investment in machinery, needs careful consideration of benefit:cost and likely return on investment.

Overcoming non-wetting is harder in these soils because the more aggressive cultivation methods, such as mouldboarding and spading, are not always suitable. High breakouts are needed on “these types of machines because remnant tree roots and rocks are common and any type of ploughing leaves these soils vulnerable to wind erosion.

Other ploughs such as Grizzly ploughs, one-way ploughs, disc ploughs, scarifiers with wide sweeps and speed tillers have been used successfully on gravelly soil. Results have been variable so local trial results and expertise should be consulted before any ploughing because a poor result, combined with increased erosion risk, can be a detriment rather than an improvement. The focus when tackling water repellence on gravel soil is commonly on low-cost crop establishment techniques such as banded wetting agents, wetting agents blanket applied to the soil surface, paired seeding boots, and sowing on or near last year’s crop row. Many of these techniques can be tested using test strips and are likely to show biggest benefits when seeding dry into moderate or severely repellent areas. Wetting agents have proven to be particularly successful on forest gravels in the south-west and precision agriculture approaches can be used to efficiently apply them to responsive repellent patches.

As with all soil, it is important to get the surface pH up to 5.5–6.0 otherwise lime will not move of its own accord down the profile to address the acid ‘choke’ at 15 cm. Often two or three lime applications are needed before any downward movement is detected, so the recommendation for this scenario is to keep applying lime regularly, every 3–5 years, to treat the band of subsurface acidity and then move to a maintenance schedule of monitoring and liming to keep both topsoil and subsurface pH at or above targets.

Although this particular gravel profile is not compacted, some gravel soils are prone to compaction. Ripping can be beneficial on gravelly soil if it is compacted. However, in this particular profile there are developed root channels and remnant roots left from the natural vegetation. These are desirable as a source of biological activity and pathways for crop roots and it would be best not to destroy that by ripping or any other deep soil disturbance.

Many farmers with gravelly soil, don’t know what their soil is like beneath the surface because of the physical difficulty in sampling to depth. There are often several soil types across a paddock with varying degrees of gravel. Deep ripping often brings up large rocks and leaves an uneven surface which then needs to be dealt with. It is also very important not to bring up sodic subsoil (unlikely in this case because it is below 50 cm). If the subsurface is not well known it is a good idea to do test strips to identify which areas are suitable for deep ripping. Deep ripping in fallow can give time for soil to settle.

On gravel soil, controlled traffic farming is likely to give less benefit than on sandy soil, particularly in soil with a very high gravel content, as the gravel itself supports machinery. Therefore, many farmers are ‘sitting on the fence’ with respect to controlled traffic farming. Those who have implemented controlled traffic have most likely done so for a whole lot of reasons other than compaction, such as more efficient seeding and use of chemicals through elimination of overlap.

In this case, deep ripping with topsoil slotting to 60 cm successfully broke up the gravel layer and the soil remains friable two years after ripping. There are now preferred pathways for roots to grow to depth so water and nutrients deeper in the profile are now available to plants.

Tissue testing commonly shows plants have better nutrition after ripping in this type of soil. This has proved to be particularly important in seasons with heavy rainfall leaching events, with plants from ripped scenarios recovering significantly more nitrogen and having greater biomass than plants growing where soil has not been ripped. In some soils, there may also be potassium available at depth.

Longer term, nutrient management on this soil may need to alter because once root growth is unconstrained, greater biomass fuelled by higher uptake of nutrients, including from depth, may mean there is greater need for fertiliser inputs.

Where this soil type is water repellent at the surface some farmers have had good results using spading in combination with deep ripping. This strategy also provides the opportunity to incorporate limed topsoil and freshly applied lime. However, the spaded soil compacts very quickly and needs ripping again after two to three years.

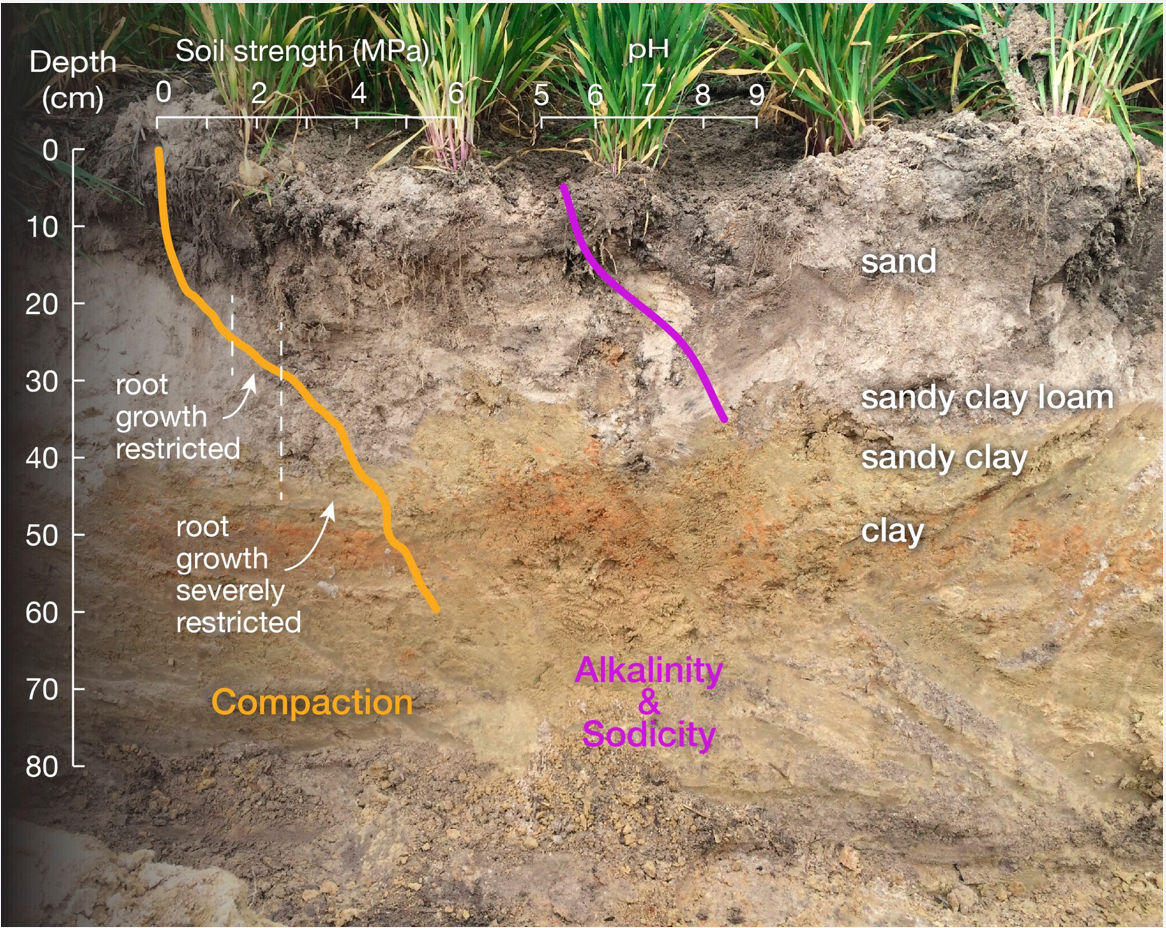

The sodic layer in this soil type causes problems, particularly when very wet when it becomes an impenetrable quagmire. This soil may also have transient salinity and boron toxicity at depth and micro-nutrient deficiencies induced by the high alkalinity.

Deep ripping with opening plates can be beneficial in this soil as the organic matter in topsoil can help stabilise the sodic clay. This improvement will not be permanent as the organic matter will be depleted over time and the chemical nature of the sodic soil causes it to deflocculate again.

Since the soil strength increases down the profile in this scenario (there is no discernible plough plan), the required depth of ripping will be the one that achieves either optimal breakout or maximum inclusion of topsoil. Depending on what deep ripper is used and the depth of ripping, a lot of clay can be brought to the surface. Subsoil clays can be toxic when brought to the surface so you need to have a good understanding of what is going to be brought up and you need to have a strategy for dealing with large clay clods brought up to the surface.

The need for spading to incorporate some of the clay will be determined by how much and what sort of clay is brought to the surface. Gypsum can be mixed in at the same time to help the clay flocculate. The benefits are usually not from the ripping removing compaction, but rather the clay ameliorating water repellence.

Care must be taken when ripping and working this type of soil because the seedbed can end up very sticky and crusting can adversely affect establishment. Ripping in this soil can be tricky as there is a limited range of moisture contents that will allow ripping to be done effectively (not too dry nor too wet). Deep tillage should be confined to soils that are achieving less than 80 % of rainfall limited yield potential and where the depth of ripping allows deeper root penetration into subsoil that is not toxic.

Trial work introducing organic amendments such as composted chicken manure has improved yield on this soil type, but the cost of doing this on a broad scale tends to be prohibitive and the longevity of the improvement is not yet known. Incorporating fresh organic matter, such as stubble, to stablise sodic clay is likely to have only short-lived benefits as fresh organic matter breaks down very quickly in soil.

General consensus on this soil profile is to manage the top 10–30 cm and adjust inputs according to potential yields. Across a whole farm there are likely to be easier, cheaper and less risky soil constraints to tackle. It is also important to recognise that in the south-east of the agricultural region alkaline grey shallow sandy duplex soil can be highly productive and requires minimal intervention; such soil is often known as Scadden sands.

This is some of the most difficult soil to ameliorate and, as such, it is usually best to manage all inputs according to the soil’s productive capacity rather than trying to increase that capacity through amelioration of predominant alkalinity and salinity constraints.

The soil is workable when moisture conditions are favourable – wet but not too wet. The surface is commonly hard setting, which hinders plant establishment and sheds water.

Some Morrel soil can be quite well structured but it is usually sodic at depth with transient salinity. There has to be an enormous amount of water in the profile for it to be available to plants because of the large osmotic effects of the high concentration of soluble salts. Often, it is possible to grow crops, but not to get any yield.

Gypsum is unlikely to be useful on this soil because it is ineffective in saline soil and it often has gypsum at depth.

This soil may be so challenging year after year that it is best excluded from the cropping system. On farms, particularly in lower rainfall areas, where other soil types have acidity as a problem, there is the potential to use the Morrell soil as a source of liming material if the carbonate content is high enough.

In some Morrell soil the problems are not so severe and in high rainfall years they can yield quite well. The focus needs to be on getting the crop to establish. Keeping stubble on the surface improves water holding and establishment of subsequent crops.

References

ebook Soil Quality: 2 Integrated Soil Management

Pluske W, Boggs G and Leopold M (2018).