Controlled traffic farming systems

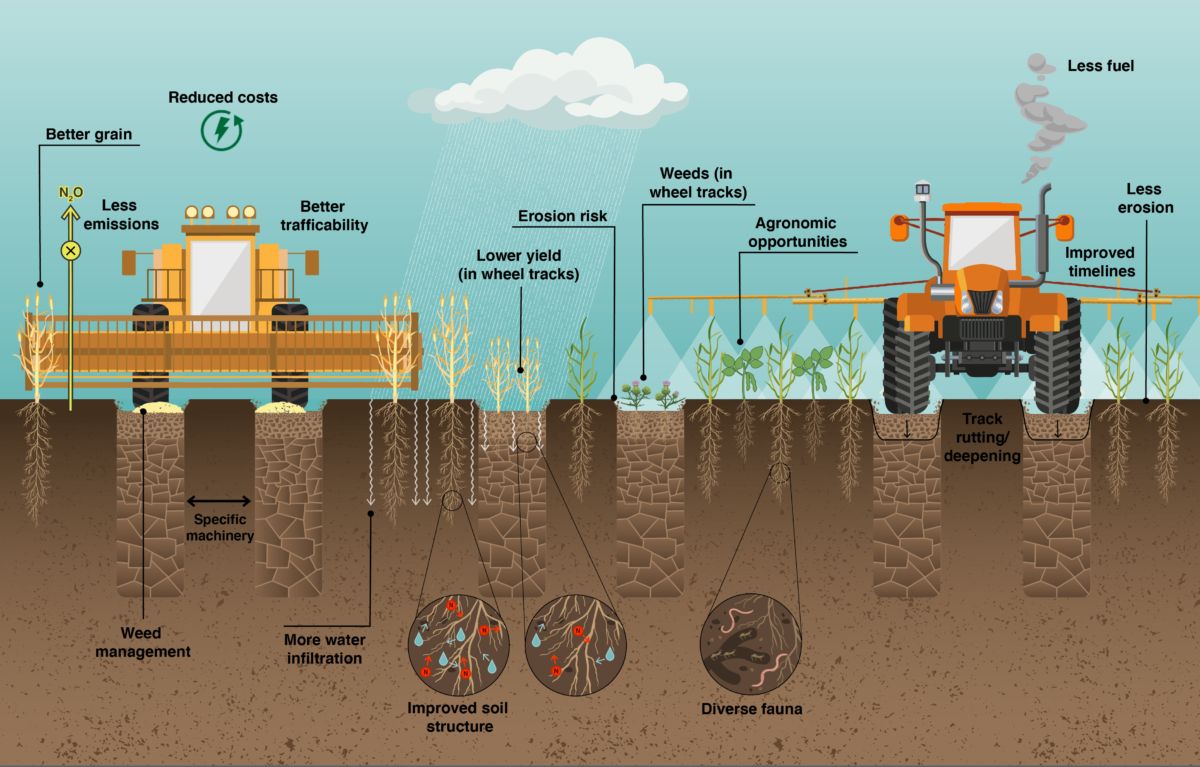

Controlled traffic farming systems minimise the area of the paddock that is compacted by heavy cropping machinery by establishing and maintaining permanent pathways for machinery.

A fully-matched controlled traffic farming (CTF) system, where tracks and machinery widths match across tractors, spray rigs and other required machinery, will traffic between 9 and 12% of the paddock. This compares to other farming systems in Western Australia in which approximately 45% of the paddock is trafficked in any one season; and where, with no traffic control, can accumulate to 100% of the paddock wheeled over a few seasons.

The confinement of traffic to permanent wheel tracks can allow loam and clay soil that naturally shrink and swell to ‘self-repair’ compaction over time. In sandy textured soil, the adoption of controlled traffic farming is essential to prevent re-compaction once compaction is removed by tillage, thereby increasing the longevity of tillage and maximising benefits.

Benefits of a controlled traffic farming system

- More grain yield (2-16% depending on soil type) and better grain quality (i.e. less screenings in wheat, higher oil content in canola).

- Reduced nitrous oxide emissions by 30-50%, potentially saving $2 to $22 per hectare in total nitrogen losses.

- Reduced costs from less overlap, better fertiliser efficiency (less nutrient leaching or waterlogging) and lower power requirement for tractors.

- Less rolling resistance and better traction running on firm wheel tracks.

- More agronomic opportunities such as relay planting, deep ripping between wide rows, precise placement of inputs and better stubble management at seeding.

- About 35% less fuel used when running on firm wheel tracks.

- Better crop growth and stubble cover reduces wind and water erosion risk.

- Improved timeliness of operations during the season, particularly in wet conditions – better floatation and less bogging.

- More micro and macrofauna in uncompact soils, like earthworms and termites.

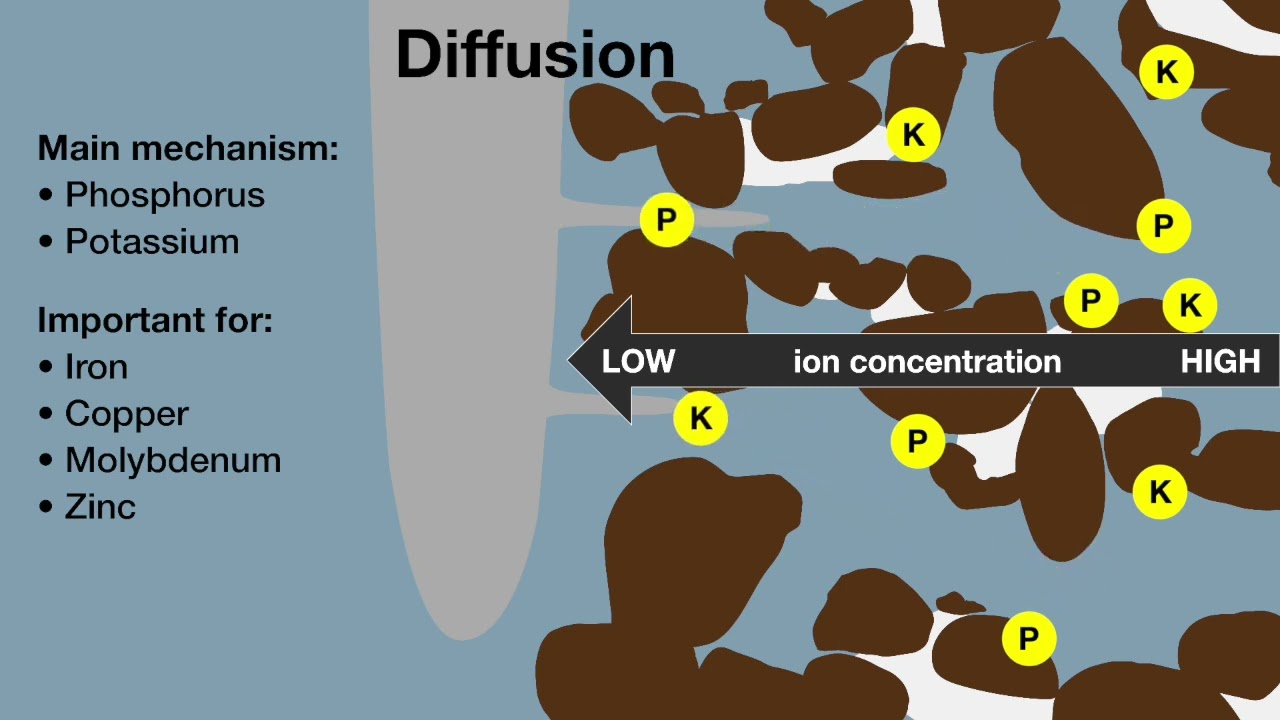

- Better soil structure leads to more root growth, increasing plant uptake of water and nutrients.

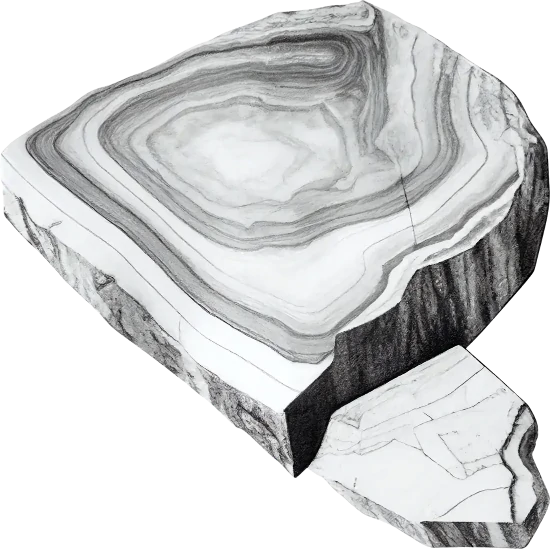

- Subsoil compaction causes slower water movement through the soil in most circumstances. Depending on soil type, the severity of compaction and the depth at which it occurs, water may not drain readily through the root zone.

- Greater opportunities for harvest weed seed management, including diverting chaff to the wheel tracks.

Risks of a controlled traffic farming system

- If wheel tracks are sown the grain yield is lower and plants can stay greener for longer at harvest (however less risk of weeds or erosion with crop in the wheel tracks).

- Risk of wind or water erosion down the wheel tracks. Paddock layouts must be planned carefully to avoid water concentrating down the tracks.

- Bare wheel tracks can become a haven for weeds.

- Wheel tracks can become rutted and deeper over time. They must be maintained to reduce erosion risk and wear on machinery.

- May be difficult to find a contractor if needed with machinery that matches the operation width and wheel track spacing, for example machinery in the multiples of 12.2 m and wheel track axle spacing of 3 m.

Establishing a control traffic farming system

Controlled traffic farming not only requires the operating widths and tyre tracks of all cropping machinery to match but also uses a guidance system to keep machinery in traffic lanes. Guidance can be as simple as a mechanical marker arm or a highly accurate automated differential global positioning system (dGPS).

Given the abundance and variation in current machinery and track widths, as well as the variability in farming systems, it often requires a significant amount of time (often up to ten years) to implement a system within a business. A controlled traffic farming system is not a ‘one size fits all’ approach and that the path of adoption differs for every business.

Farm layout planning is essential to maximise operational efficiency and reduce the risk of erosion in a controlled traffic farming system.

The wheel tracks can act as mini drains or channels for water, promoting run-off and erosion. Preventing water shedding into wheel tracks from other areas in the paddock and maintaining the wheel tracks to prevent them becoming rutted will decrease the risk of erosion and increase the potential entry of water into soil that then becomes available to plants.

Further reading

External link Developing a controlled traffic (tramline) farming system

Stephen Davies, Derk Bakker, Jeremy Lemon, David Hall, Bindi Isbister. Department of Primary Industries and Regional Development.

Tool or calculator CTF Calculator

Department of Primary Industries and Regional Development, GRDC and Precision Agriculture.

Publication Controlled traffic farming manual

Developed by Northern Agricultural Catchments Council (2013). Authored by Bindi Isbister, Paul Blackwell, Glen Riethmuller, Stephen Davies, Andrew Whitlock and Tim Neale.

In 2019, a survey of 80 Western Australian grain producers estimated 25% of farmers were using some form of controlled traffic farming, with a further 24% intending to implement a system in the future.

A large hurdle to the adoption of controlled traffic farming reported by farmers is cost, with case studies conducted over the past twenty years showing the average cost of conversion to controlled traffic farming estimated at $45 000. Largely, these costs were associated with modifying wheel track spacing and operating width of existing machinery.

New machinery is expensive and mismatched tracks and/or machinery width within the machinery fleet, can mean a significant cost to replace machinery where required. To minimise these costs, a longer-term adoption and implementation of controlled traffic farming is achievable by replacing old machinery over time as required/economic with new machinery that meets planned track and operational widths.

While capital machinery purchases have likely constrained the adoption of controlled traffic farming, at the time of the 2019 survey, a growing demand from farmers for matching implement widths was reflected by machinery dealers reporting an increase in the level of enquiries.

Using the CTF Calculator as a planning tool

Matching machinery width and tracks to establish a controlled traffic farming system can be a daunting prospect, particularly where current machinery is of variable dimensions. The ‘CTF Calculator’ is a useful web-based tool that can assist farmers and their consultants with machinery investment planning. The calculator estimates the percentage area of the paddock that is ‘wheeled’ by different machinery combinations, and calculates the estimated areas impacted and thus the benefit of managing compaction through the adoption of controlled traffic farming. Users enter their current machinery specifications into the calculator for each farming operation – for example, seeding tractor, air cart and bar, or spreading tractor and spreader to determine the area wheeled for each farming operation, and an overall combined wheeled percentage for all operations over the season.

Users can choose to select from a library of pre-loaded machinery options, or specify their own current tyre size, track gauge (i.e. tyre centre to centre dimension) and operating width. The user can then compare various combinations of proposed new and modified machinery to match track gauges and reduce wheeling percentage in the calculator.

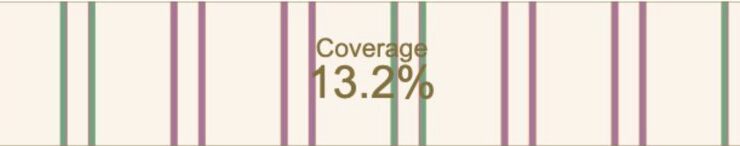

In the example provided, an unmatched and matched wheel system was compared using the CTF Calculator. Where the machinery fleet was not matched, a wheeled area of almost 43% was calculated, compared to a fully matched controlled traffic farming system on 3-metre track gauge with a wheeled area of just 13%.

The economic benefit of any changes can then be calculated from a compaction penalty associated with different soil types (either pre-determined or input by user), together with the grain price and yield.

In this example, assuming a grain price of $220 per tonne and average grain yield of 2 tonnes per hectare, the estimated benefit of adopting a fully matched controlled traffic farming system on a sandy soil type where a compaction penalty of 30% applies is $47 per hectare. A benefit of $15 per hectare is achievable on a red loam soil, with a lower compaction penalty of 10%.

The calculator can also be used to evaluate how changing machinery specifications would alter the percentage of the paddock wheeled. For example, if upgrading machinery in a controlled traffic farming system running a 36.6-metre sprayer, 12.2-metre header and 18.3-metre seeder combination, to a 55-metre sprayer and an 18.3-metre header so it matches 3 to 1, the wheeled area is reduced from 18% to 13%.

Assessing the impact of matching machinery and the potential benefits of controlled traffic farming can help inform future investment decisions. It is usually not economically feasible to convert to match all machinery in one or two seasons. But changing machinery in line with an existing farm machinery investment plan is a good approach to develop a fully matched controlled traffic farming system without incurring the massive expenditure of a rapid change. Many successful controlled traffic farmers have taken 8 to 10 years to develop a fully matched controlled traffic farming system – but the key to success over any timeframe is to develop a machinery plan to achieve the controlled traffic farming system you want, and then stick to it, even if it takes longer than planned.

Using the controlled traffic farming calculator

The controlled traffic farming calculator can be used to calculate how much of your paddock is wheeled. From Soil Quality: 6 Soil Compaction (Parker et al. 2021). Video talent: Bindi Isbister, DPIRD; video production: Ralf E Mulks, Filmmaker, Geraldton.

Page references and acknowledgements

Material on this page adapted from:

- Parker W, Isbister B, Hoyle FC and Leopold M (2021). Soil Quality: 6 Soil Compaction. SoilsWest, Perth, Western Australia. [Access]

Last updated July 2024.