What is fertiliser?

Fertilisers are materials that supply nutrients to crops and pastures when the supply from soil and plant residues is low and constraining growth.

What is the role of fertiliser?

Fertilisers replace nutrients that are removed or lost from soil.

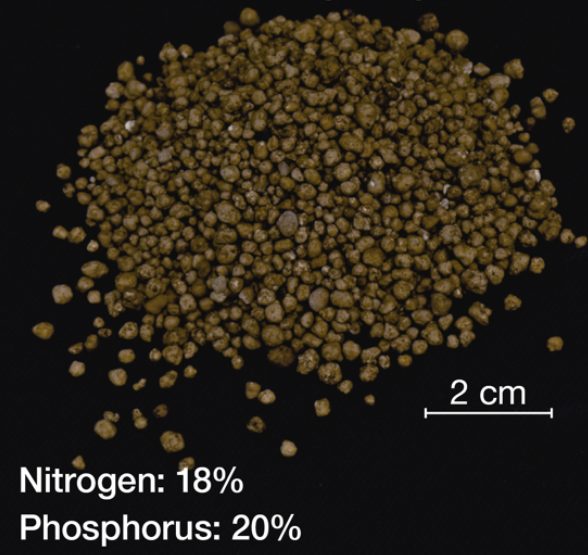

Fertilisers may supply single nutrients, such as urea or urea-ammonium nitrate (UAN), which supplies only nitrogen. They can also supply several nutrients, such as di-ammonium phosphate (DAP) and nitrogen-phosphorus-potassium (NPK) compound fertilisers. Farmers can now obtain a variety of blends of fertilisers that are tailored for their particular farming system and soil type.

Common crop and pasture fertilisers

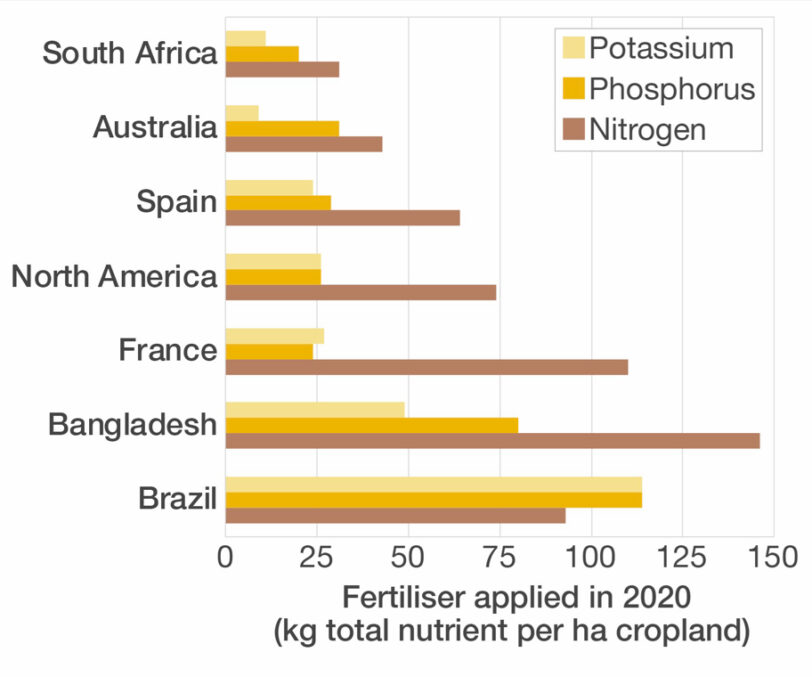

The types of fertilisers used in agriculture have changed over the last half century.

As the area and range of soil types on which crop and pasture production has expanded, fertiliser products have been developed to include other nutrients like copper, zinc and manganese to overcome soil and plant deficiencies. In recent years, a focus on replacement of soil nutrients has resulted in the application and rate of potassium fertiliser having increased as soil stocks have been, and continue to be, depleted by higher rates of grain production. Larger sowing areas and time critical management has also meant more recently, a shift to fertilisers higher in phosphorus is evident as logistics become more important at sowing – with more area able to be planted between refilling air seeders. The amount of nitrogen imported in urea has increased as cropping area has increased, while the contribution of fixed nitrogen by legume crops and pastures has decreased.

Fertiliser use over time

Nutrient management is a critical component of profitable farming systems in the south-western agricultural region of Western Australia, where historically nutrient supply from soil and plant residues was not adequate for crop and pastures to reach their water-limited yield potential. Fertilisers were used to meet this gap in supply and over the past ten years have often been the highest variable cost to the farm business.

Over the last three decades, broadacre farming systems have shifted from a dominance of grazing (60% of arable area as pasture), to about 60% of arable area cropped. During this time, there has also been a shift towards non-legume crops which has increased nutrient demand and altered nutrient cycling.

Nutrient management in farming systems in Western Australia

From: Soil Quality: 10 Plant Nutrition (Scanlan et al. 2023). Video: Red Empire; still photos courtesy DPIRD.

Over the past decade, fertiliser expenditure for grain producers has been the highest variable cost, accounting for 60% of costs in cropping. Over the same period, commodity imports have increased by as much as 250%.

From: Soil Quality: 10 Plant Nutrition (Scanlan et al. 2023). Chart: Australian Bureau of Agricultural and Resource Economics and Science (2023) Commodity Statistics data. Video and animation: Science with Style.

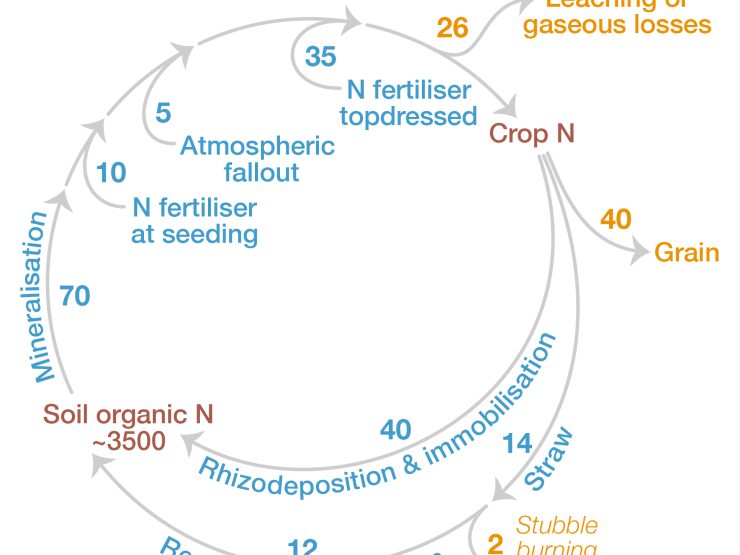

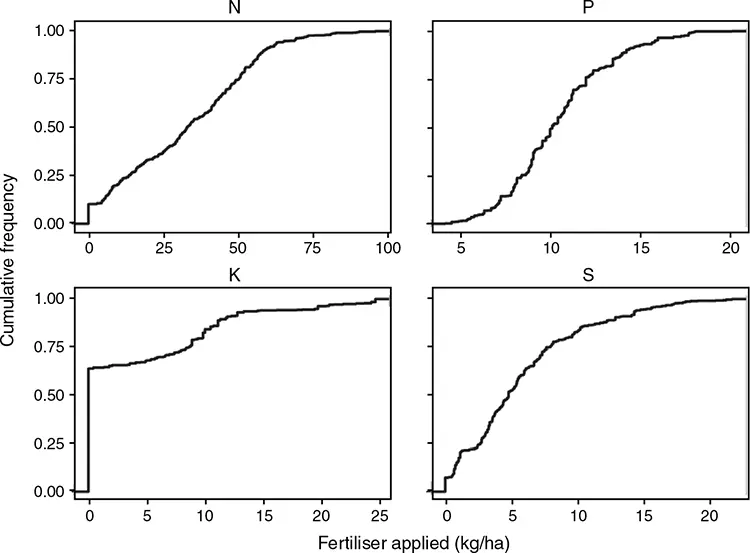

Nitrogen

In many soils in the south-western agricultural region of WA, the supply of plant-available nitrogen will be inadequate at some stage to support rainfall-limited plant growth. While mineralisation of soil organic matter and plant residues supply nitrogen, this is not always available during peak demand. Hence, management of nitrogen fertiliser to maximise efficiency of use is a requirement for production.

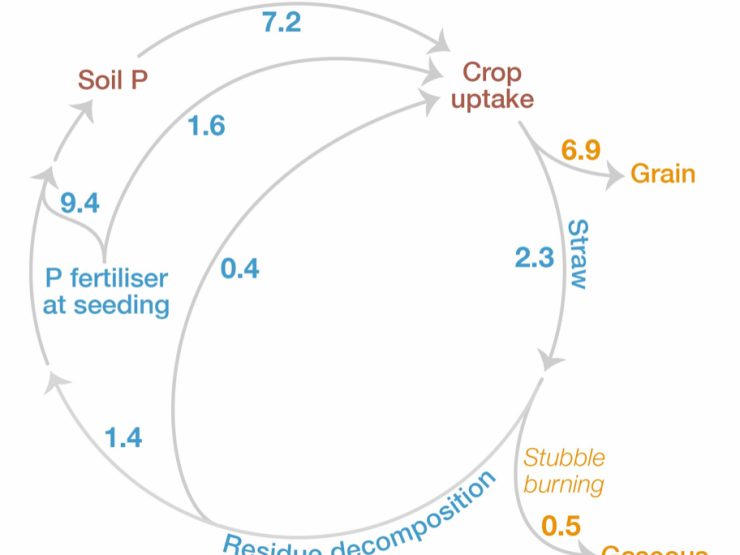

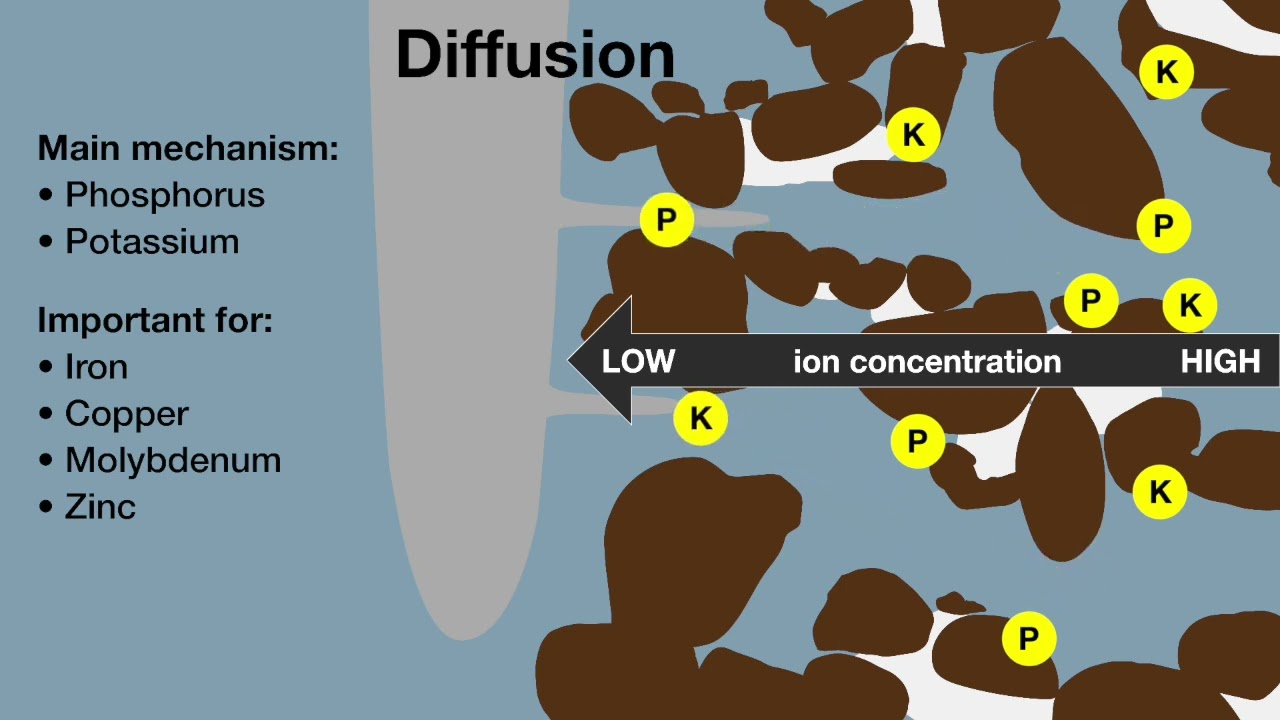

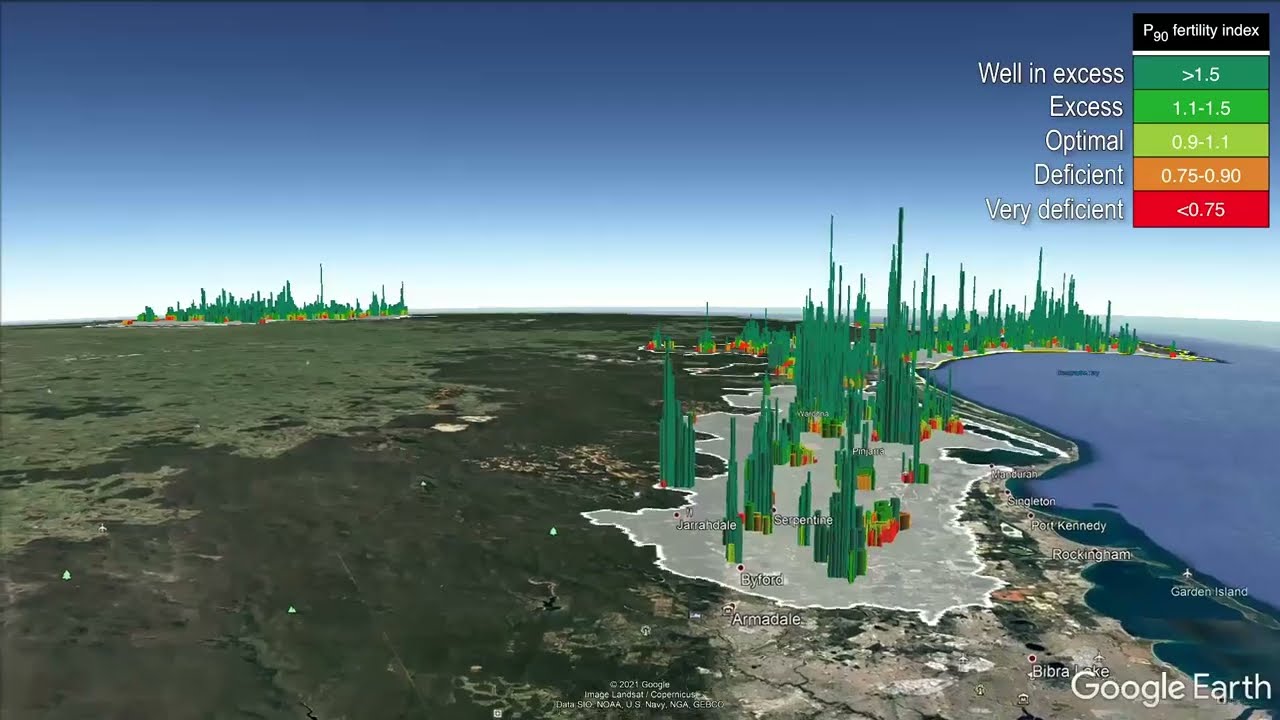

Phosphorus

Historically, the focus of fertilisers was on phosphorus sources such as superphosphate, as phosphorus deficiency was almost a universal limitation to crop and pasture production in Western Australia. Several decades of continuous application of phosphorus fertilisers has resulted in a gradual accumulation of plant-available phosphorus and total phosphorus in soil. Currently, inadequate levels of phosphorus are largely confined to soil with very high phosphorus buffering index (PBI), such as forest gravels or deep pale sands, on which phosphorus leaching depletes topsoil phosphorus.

In the south-western agricultural region of WA, the strategy of fertilisation has changed in the decades since new land was first farmed. The initial aim was to build nutrient levels, especially phosphorus and micronutrients. The current fertiliser approach for phosphorus is predominantly maintenance, since soil reserves have built progressively to a point where they are adequate, or close to adequate, for production.

Accumulation of phosphorus in high rainfall pasture soil in Western Australia

From: Soil Quality: 10 Plant Nutrition (Scanlan et al. 2023). Content by David Weaver, DPIRD. Video: Science with Style.

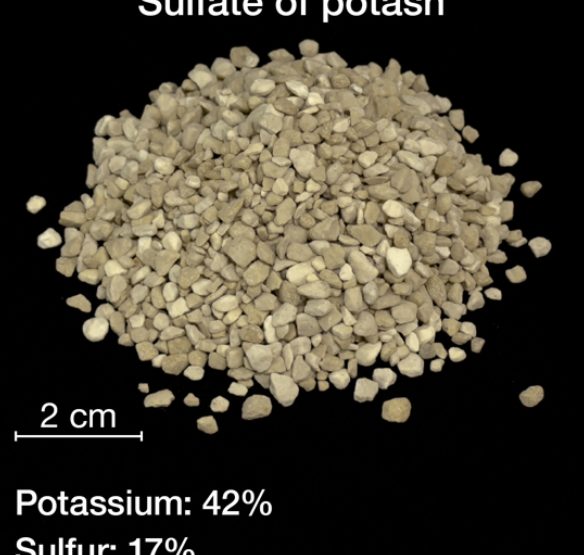

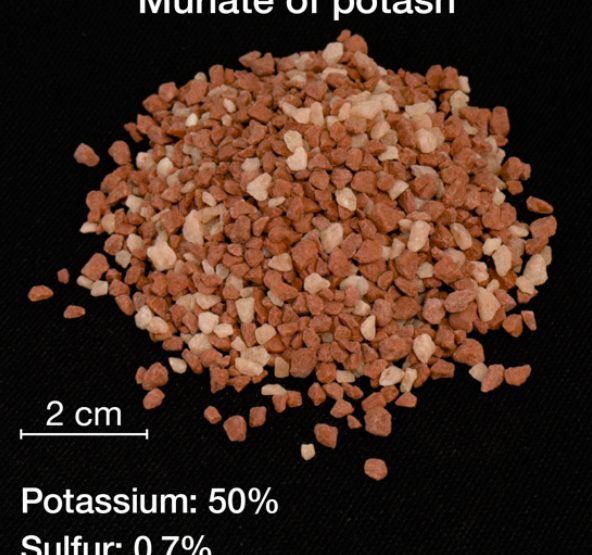

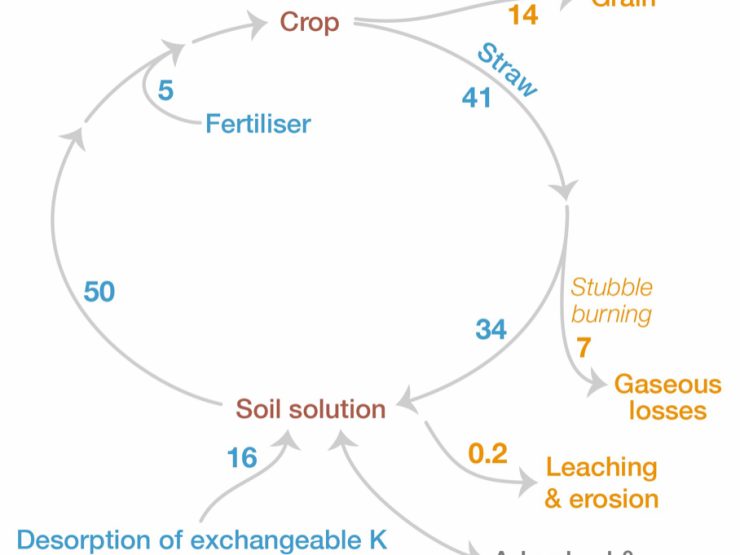

Potassium

Potassium balances have been consistently negative over at least the last three decades in the south-western agricultural region of Western Australia. While potassium deficiency appeared on deep sands on new land, it is now becoming more common on duplex soil types and loam soil types.

Other nutrients

Deficiencies of other essential plant nutrients vary with soil type and plant species. For example, calcium concentration varies greatly – with calcareous and alkaline soil types containing adequate available calcium, but sand having low natural values of plant-available calcium. While historic applications of superphosphate have helped maintain adequate supplies of calcium to sandy soil, future availability may depend on fertiliser use.

Similarly, sulfur balances were once typically positive in many farming systems associated with the application of superphosphate. Shifts to diammonium phosphate (DAP) and monoammonium phosphate (MAP) as the primary phosphorus sources have changed the average sulfur balance from positive to negative in many cropping systems. The exception to this, is land used for canola production which has a high sulfur requirement, and farmers commonly apply generous applications of gypsum to maintain a positive sulfur balance.

Low levels of zinc, copper and molybdenum are common in Western Australian soil. Due to the application of fertilisers, and in some cases regular supplementary application in fertiliser and a long residual value in soil, deficiencies of these micronutrients for crops are now comparatively rare.

Fertiliser best management practices

Best management practices for fertiliser are captured in the ‘4 Rs’ slogan which identifies the need to consider the right rate, the right form, the right time, and the right placement in order to optimise nutrient use efficiency from fertilisers. These four areas of decision making are influenced by the expected profit and logistics associated with the different options, and the best approach depends on the crop grown, soil type and rainfall. Choices about fertiliser source, rate, timing and placement influence profit through a change in grain or pasture yield and quality.

-

Right rate

-

Right form

-

Right time

-

Right place

Source of fertiliser

Fertiliser can be either synthetic or organic. Synthetic fertilisers are manufactured and are the most commonly used type of fertiliser for crop and pasture production in most broadacre agricultural regions of Australia. Products such as urea, monoammonium-phosphate (MAP) and muriate of potash (MoP) have a high concentration of nutrients and are cost-effective to transport.

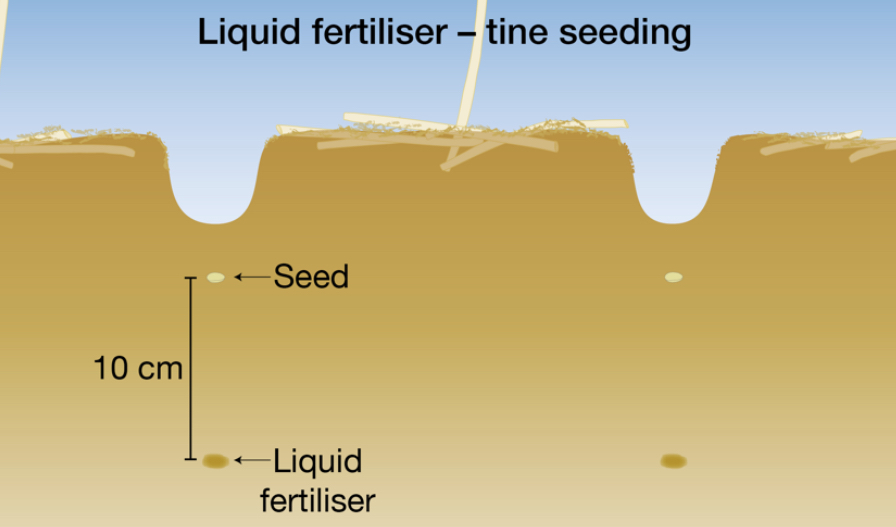

In the south-western agricultural region fertilisers are mostly supplied in granular form because they are best suited to the fertiliser delivery systems in air seeders and spreaders. Use of the liquid fertiliser urea-ammonium nitrate is also increasing with application either by banding at seeding, or foliar application during the growing season. Liquid fertiliser provides flexibility for application and storage.

Rate of fertiliser application

Fertiliser rates are the most easily changed component of fertiliser decision making and are informed by variables such as soil testing, climate predictions and paddock history. Fertiliser rates are determined based on achieving a specific production goal or target:

- An optimal rate based on a predicted economic response curve

- Replacement of nutrients that have been exported in the previous crop

- Build-up soil fertility

Timing of fertiliser application

Timing of fertiliser application is used to improve nutrient use efficiency.

In grain production in WA, farmers apply two to three applications of nitrogen fertiliser to mitigate the risk of leaching beyond the crop root zone. Split applications of nitrogen fertiliser also let farmers to adapt their level of investment in nitrogen fertiliser as the season progresses, as seasonal conditions provide a better estimate of yield potential for the crop.

For pasture production, phosphorus fertiliser is usually applied after germination. In high rainfall areas, split phosphorus applications in autumn and late spring are recommended to better align the timing of supply with plant demand.

Placement of fertiliser

Choice, timing and placement of fertiliser differs as the growing season progresses and can be influenced by cost, practicality as well as optimal efficiency of use. Form, timing and placement are often factors considered in improving nutrient use efficiency.

- Surface application: suitable for pre- and post-sowing in cropping systems and the primary application method for pastures. e.g. spreading urea, ammonium sulfate, gypsum (source of sulfur), or muriate of potash in the weeks leading up to sowing.

- Banding at, or below the seeding depth is largely associated with cropping and can be associated with a higher nutrient use efficiency than surface application. e.g. granular (e.g. monoammonium-phosphate – MAP) and liquid (e.g. urea ammonium nitrate – UAN).

- Foliar application of liquid fertilisers suitable for post-emergence.

Use of GPS guidance and spreader calibration can improve the evenness of application and effectiveness of fertiliser applied. For surface application, fertiliser distribution patterns can be improved by running tests using catch trays before and after modification of a spreader or its settings.

Nitrogen management following deep ripping of soil

Alleviating soil compaction allows plant root access to a greater volume of soil moisture and increases nitrogen use efficiency. From: Soil Quality: 6 Soil Compaction (2021). Talent: Richard Quinlan, Planfarm. Video: Lomax Media.

Fertiliser application techniques

Banding granular fertilisation through a tine module offers benefits like efficient nutrient use, reduced seedling stress, and focused application. Placing nutrients close to the seed enhances uptake during crucial growth phases, while minimising damage risk. It lessens nutrient loss, promotes uniformity, and suits conservation tillage.

Image: Science with Style

Banding granular fertiliser using a disc module provides benefits such as precise nutrient delivery, reduced seedling stress, and efficient use of resources. Nutrients placed near the seed aids uptake during crucial growth stages. It minimises nutrient loss, encourages uniform growth, and works well with minimum tillage.

Image: Science with Style

Deep banded liquid fertiliser application offers benefits such as targeted nutrient placement, reduced seedling stress, and efficient nutrient utilisation. Placing nutrients deeper in the soil promotes effective uptake during critical growth stages without harming seedlings. This method minimises nutrient loss, encourages uniform plant growth, and aligns well with conservation tillage practices. There can be cost savings and reduced weed competition, but nutrient availability may be limited for surface rooted plants.

Image: Science with Style

Understanding granular fertiliser spread patterns can lead to significant cost savings and benefits for farming. Fertiliser is expensive, so efficient fertiliser use, optimal pasture growth, and minimal offsite effects are crucial considerations. A single broadcast spreader pass results in higher application rates at the centre and lower rates farther away from the spreader. Even distribution is achieved by overlapping previous spread runs. The distance between spreader runs is termed ‘bout width’. The goal is to maintain less than 15% variation in application levels across the paddock (coefficient of variation).

Uneven application leads to insufficient fertiliser in some areas, reducing pasture growth, while over-fertilisation near the centerline diminishes profitability and increases offsite nutrient risks. Achieving even fertiliser distribution at the widest bout width also reduces fuel and time costs and minimises paddock compaction.

Farmers and contractors often rely on visual cues to assess fertiliser spread, gauging it by the distance granules appear to be thrown. However, particles falling at 25 metres does not guarantee even coverage.

Accu-Spread® is an Australian program, testing and accrediting fertilser spreading equipment for accuracy and evenness of spread. Assessments undertaken in Accu-Spread® demonstrate variations in spread patterns and fertiliser distribution are linked to factors like fertiliser type, fine-particle content, spreader type, and modifications.

Fertilisers with low fine-particle content (<2mm) can be spread over wider bout widths than those with high fine-particle content.

Precision spreaders typically show wider bout widths compared to multi-spreaders.

Spreader modifications can increase bout width. Prior to modification, only 8% of spreaders achieved a coefficient of variation of 15% or less when spreading superphosphate at 25-metre bout widths, rising to 32% after modification. For urea, these figures were 19% before modification and 31% after.

Modifications such as replacing the V section for fertiliser distribution onto spinners led to a 14% increase in urea bout width and a 59% increase for superphosphate. Swapping spinner blades resulted in a 20% boost for urea and 31% for superphosphate. Modifications combining V section replacement and new blades saw similar improvements. Other adjustments like vane or blade repositioning and altering spinner speeds increased bout widths by 5% to 32% depending on the fertiliser type.

Photo: Angie Roe Photography

For effective liquid fertiliser application, attention to detail, proper equipment maintenance, and adherence to best practices are essential. By tackling common issues and enacting suitable solutions, farmers can ensure precise and efficient nutrient delivery to crops and pastures while mitigating detrimental environmental effects.

Below are some specific challenges to address:

Uneven distribution

Maintain and calibrate spray equipment consistently to ensure steady flow rates and optimal nozzle performance. Utilise drift-reducing nozzles to enhance coverage and diminish the risk of uneven distribution.

Spray drift

Opt for specialised nozzles designed to minimise drift. Adjust application settings based on weather conditions, including wind speed and direction. Create buffer zones and employ suitable spraying techniques to prevent unintended movement.

Nozzle clogging

Filter liquid fertiliser before it enters the spray system. Regularly inspect and clean nozzles to eliminate accumulated residue. Choose nozzles with anti-clogging features to prevent disruptions.

Droplet size and coverage

Select nozzles that yield consistent droplet sizes suitable for the particular crop or pasture and growth stage. Adjust spray pressure and nozzle type to achieve the desired droplet size for effective coverage.

Chemical compatibility

Prior to application, assess the compatibility of liquid fertilisers with nozzle materials and other chemicals. Opt for nozzles crafted from materials resistant to chemical interactions.

Environmental impact

Adhere to recommended application protocols to minimise the risk of nutrient runoff. Implement best management practices, such as avoiding application prior to heavy rainfall and adhering to local regulations.

Operator error

Provide comprehensive training to operators regarding equipment operation, upkeep, and optimal practices for liquid fertiliser application. Consistently review and reinforce proper application procedures.

Photo: Department of Primary Industries and Regional Development

Photo: WA Department of Primary Industries and Regional Development

Streaming nozzles, also known as streamer nozzles or liquid fertiliser injection nozzles, are specialised devices used in agricultural spraying and irrigation systems to apply liquid fertilisers directly to the soil or crop foliage. These nozzles are designed to create a concentrated stream or jet of liquid, allowing for accurate and targeted application of nutrients, pesticides, and other agricultural chemicals.

Streaming nozzles differ from traditional spray nozzles, which produce a fine mist or spray pattern. Instead of creating small droplets, streaming nozzles release a focused liquid stream, which can be advantageous for certain applications, such as injecting liquid fertilisers into the soil, delivering precise doses of chemicals, or treating specific areas within a paddock.

Streaming nozzles face many of the same issues as spray nozzles, except that they are less subject to drift because of larger droplets. Streaming nozzles also reduce the wetting of foliage, reducing the risk of foliar disease. It is important to note that streaming nozzles are not suitable for all applications. They work best in situations where localised application is desired, such as banding fertilisers along rows or applying herbicides to the base of weeds. They may not be suitable for foliar application or situations where complete coverage of plant foliage is necessary.

Photo: Department of Primary Industries and Regional Development

Integrated nutrient management

Integrated nutrient management is the utilisation of a number of sources to meet crop demand; fertilisers, crop residues and soil nutrient supply.

The longer-term effects of fertiliser application and crop sequence on nutrient supply are an important component of nutrient application decisions. The longer-term (also called the residual) effect from phosphorus fertiliser is an important component of decisions.

Experiments that have utilised phosphorus isotopes as fertiliser to quantify its fate have shown that, on average, only 15% of applied phosphorus is recovered from fertiliser in the year of application; most of the phosphorus uptake is derived from the cycling of residual soil phosphorus . Grain producers also apply copper, zinc and manganese above the annual requirement because there is a residual benefit to future crops.

Deep-rooted legume crops and pastures may also play an important role in potassium cycling. A four-year field trial found that total potassium in the top 100 centimetres increased with continuous blue lupin (Lupinus consentinii), whereas it declined in the continuous subclover treatment. Leaching losses are likely to be greater where only shallow-rooted crops are grown, because less potassium is being taken up from the subsoil and cycled to the soil surface in plant residues.

Residue management can have an influence on nutrient supply. The concentration of nutrients in windrows, or unevenly spread crop residues during harvesting can lead to uneven growth. Better growth on windrows from previous years is often due to potassium supply; where producers are harvesting on the same run lines every year, soil potassium is depleted at the outside edge of the header swath and accumulates in the middle of the swath due to uneven redistribution of potassium in crop residues. This ‘windrowing effect’ is a useful diagnostic method for detecting when soil potassium supply is marginal.

Citations

2019 Nutrient management challenges and opportunities in conservation agriculture.

Angus, J., Bell, M., McBeath, T., & Scanlan, C.

2012 Wheat grain nutrient concentrations for south-eastern Australia

Norton, R. M.

How does the crop response to fertiliser interact with soil?

The yield response of crops and pastures to fertiliser application can be affected by soil constraints.

Soil compaction reduces the nutrient use efficiency for fertiliser nitrogen. Field trials in the south-western agricultural region of Western Australia have shown that deep ripping compacted soil can increase nutrient use efficiency by 18–60%. The improvement in nutrient use efficiency after deep ripping is attributed to better root growth in the subsoil, allowing greater capture of water and nitrogen.

Ameliorating soil acidity with lime application can change the availability of micronutrients. As pH increases, the concentration of copper and manganese decrease and molybdenum increases. In soil with very low copper and manganese levels, deficiency of these micronutrients may be exacerbated. In field research in the south-western agricultural region, the decrease in copper and manganese uptake in plants has been subtle, even at sites where lime application has increased surface pH by more than 1 pH unit.

Similarly, lime application to acidic soil can increase the yield response to phosphorus fertiliser application where the lime application has led to a reduction in subsoil aluminium toxicity.

PAGE REFERENCES AND ACKNOWLEDGEMENTS

Material on this page adapted from:

- Hoyle FC (2007). Soil Health Knowledge Bank.

- Scanlan C, Weaver D, Bell R, Borrett R and Cheng M (2023). Soil Quality: 10 Plant Nutrition. SoilsWest, Perth, Western Australia. [Access]

Last updated July 2024.