Soil amelioration

Soil amelioration is the targeted intervention to overcome single or multiple soil constraints to plant production. Soil amelioration typically includes the addition of soil amendments and/or mechanical manipulation of the soil profile. Consider crop and pasture rotations that benefit soil structure, ground cover, fertility and disease control, as well as a traffic management plan to maximise the longevity of soil amelioration interventions.

It is important to sufficiently diagnose the restrictions on plant growth to ensure best return on investment. Quite often multiple constraints are present and optimal management options may target many at the same time.

Mechanical interventions

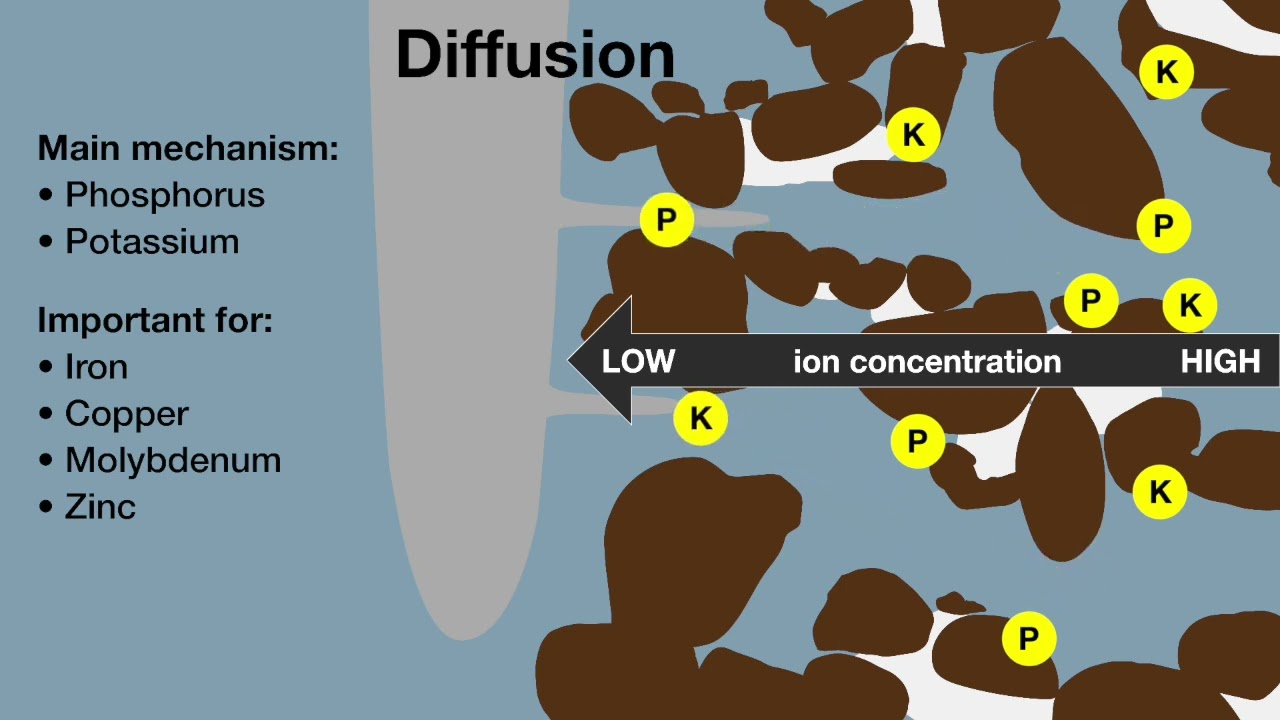

Deep working at seeding involves the use of deeper working points during the seeding operation to cultivate below the seed, partially removing the hard pan that commonly occurs below usual working depth. Seeding equipment with tillage points capable of cultivation to depths between 100 and 240 millimetres provide benefit to crops through alleviation of shallow compaction. Root growth is encouraged to the depth of tillage, with corresponding benefits to crop production. Grain yield responses in wheat of between 32 and 50 kilograms per hectare have been attributed to every centimetre of tillage below the surface.

The disadvantage of this approach is that subsurface compaction below the working depth of seeding equipment will remain. As a result, yield responses are likely to be lower than deeper tillage, particularly when crop roots are unable to access the moisture below the remaining compaction layer.

Deep ripping refers to tillage working to depths greater than 300 millimetres. An implement with strong deep working tines is pulled through the soil to shatter and loosen hard pans within the depth of ripping. This allows root access through the hardened layer and access to water and nutrients in unconstrained layers beneath. Deep ripping benefits can include:

- decrease in extent and severity of compaction and soil strength

- vigorous early crop root growth

- improved water and nutrient capture and use by the crop

- increased water infiltration (dependent on soil type)

- increased crop biomass, grain yield and grain quality.

While deep ripping can increase yield, careful management is required to maximise benefits. Risks following deep ripping include poor plant establishment, bogging in soft soil, and crops ‘haying off’ during hot, dry season finishes as a result of high early plant biomass accumulation. Typical yield responses from standard deep ripping (300–400 millimetres) are 200 to 500 kilograms per hectare and very deep ripping (300–700 millimetres) about 600 kilograms per hectare. While deep ripping can increase yield, careful management is required to maximise benefits. Risks following deep ripping include poor plant establishment, bogging in soft soil and crops ‘haying off’ during hot, dry season finishes.

Topsoil inclusion plates are a pair of steel plates that fit to the rear of a ripping tine, holding open a slot in the soil as the tine passes through, and allowing topsoil to fall into the slot behind the tine. In this way some of the topsoil containing organic matter (or other ameliorants) and applied lime makes its way into the subsurface soil in narrow channels. These channels form pathways for preferential root growth through inhospitable soil, and access to soil resources at depth.

Topsoil inclusion plates have been investigated for their benefit in cropping situations and have been shown to assist with the incorporation of both lime and organic matter from the surface into the subsurface soil, helping to alleviate these constraints. Trends of increased pH and organic carbon have been measured between 200 and 300 millimetres depth, within the slotted zone, when compared to soil that has not been ripped. Deep ripping with topsoil inclusion can increase yield by one tonne per hectare.

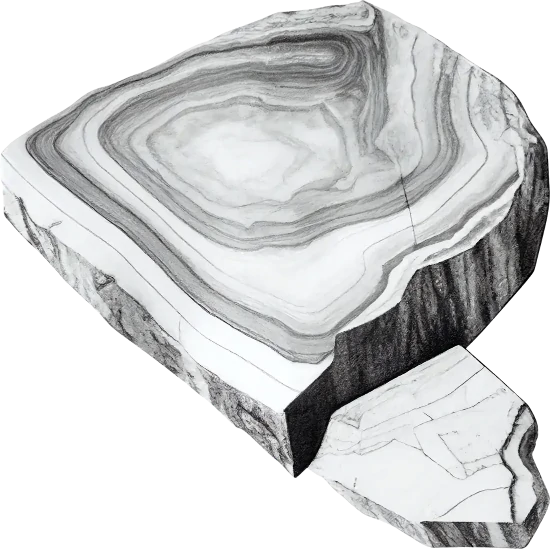

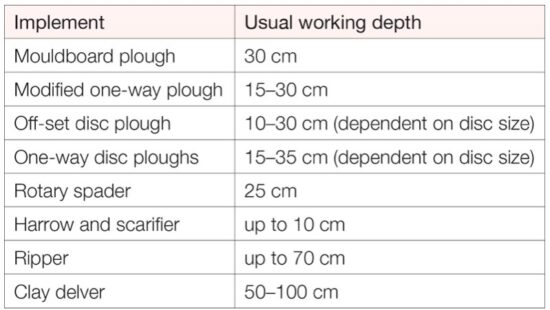

Soil mixing operations loosen soil and have a similar effect to deep ripping, opening the soil structure and removing compaction to the extent of their working depth – but with a greater extent of blending the topsoil and subsurface soil. Rotary spading loosens and mixes the soil to a depth of 300–400 millimetres. Rotating spades bury about 70% of the topsoil and lift seams of subsurface soil to the surface. Offset disc plough are a cheaper option to spading and work better in gravel soils. The average yield response of large offset discs is 500 kilograms per hectare and spading 600 kilograms per hectare. Soil mixing leaves the surface more prone to erosion than deep ripping, so timing is a key consideration. It is more relevant for ameliorating other constraints particularly soil water repellence (hydrophobicity) and the application of lime to a greater depth to manage acidic subsurface soil.

A mouldboard plough consists of skimmers and plough boards that invert soil into furrows. They are very effective at burying topsoil. Mouldboard ploughs do remove compaction to the bottom of their working depth (350–400 millimetres) however they are more commonly used to address other constraints including water repellence, managing herbicide resistant weeds and acidic subsurface soil. Because the topsoil is buried they do leave the soil more susceptible to erosion therefore it is recommend ploughing be done in winter once the soil is wet. Poor plant establishment can also occur due to surface crusting from too much subsurface clay or acid soil being turned up or improved efficacy of herbicides. Yield response to mouldboard ploughing are typically 500 to 400 kilograms per hectare.

Modified one-way ploughs are a cheaper means of inverting soil given the lower capital cost to buy a one-way plough and modify it. To achieve a better inversion of soil the ploughs are being modified by removing every second disc that allows enough space for the soil to turn over. Fitting bigger, scalloped discs 700–750 millimetres also helps turn more subsoil and bury the topsoil. One-way ploughs also work effectively in gravel soil as long as there aren’t too many cemented rocks or boulders. They can be set up to work to a similar depth of a spader or mouldboard plough 350–400 millimetres and can achieve a similar crop response with an average 900 kilogram per hectare yield response.

Soil movement during ripping

Deep ripping is used to fracture and loosen hardened soil. From Soil Quality: 6 Soil Compaction (Parker et al. 2021). Voice talent: Wayne Parker, DPIRD; animation: Bee Box Marketing.

Strategic deep tillage tips and techniques

Deep ripping and topsoil slotting

- It is important to identify the soil types that can be deep ripped and most likely to respond to ripping/topsoil slotting. Importantly, you need to identify the depth of hard-pan to know how deep to rip. Paddocks that have several soil types can be challenging.

- Deep ripping can bring rocks and old tree roots to the surface so you need to know what is underneath beforehand.

- Inclusion plates disturb more of the soil and increase draft so many farmers find they need to take inclusion plates on and off on a paddock-by-paddock basis, which highlights the importance of a good knowledge of your soils.

- Slotting topsoil works best when the surface soil is dry so it flows into the slot. If there is some soil moisture, it may be best to go for depth rather than using inclusion plates, depending on what is the most limiting factor.

- An uneven soil surface can be problematic for seeding so when ripping you need to check that you are not leaving ridges. Unevenness can be more of a problem after deep ripping with inclusion plates and rolling will usually be required to prepare the seedbed. Caution is required as laying down stubble can increase erosion risk. Less rolling is required if the plates are taken off, a coil packer may be sufficient, otherwise a rubber tyre or other weighted roller is needed.

- Ripping is usually done before seeding, however if not too wet, spring ripping does allow time for soil to re-settle and clods to weather, resulting in a better seedbed. In spring, soil is usually moist and care is needed to determine if it is too wet. Ripping needs to produce fracturing of the soil without smearing—if it is too wet, don’t rip.

- The decision whether or not to rip using inclusion plates needs to take account of the most limiting factor, likely effectiveness of the topsoil inclusion and the increased erosion risk from increased disturbance and reduced stubble cover.

Soil mixing

- Undertake good baseline soil testing, in 10 cm increments, to 10 cm below the working depth of the deep tillage tool you are going to use. Get the soil analysed for pH, salinity and nutrients. Take enough samples to understand the soil variability across the paddock, including for texture change, stones and gravel. Assess compaction using a handheld penetrometer or push probe.

- Do not bring to the surface strongly alkaline clay subsoil that are dispersive (sodic), saline or have toxic concentrations of boron or chloride. Be aware of bringing strongly acidic subsoils to the surface, this may require additional applications of lime after amelioration.

- Choose a soil mixing option which will best address the constraints your soil has. When incorporating amendments such as lime, nutrients or clay subsoil, more thorough mixing is often needed. This is often achieved with rotary spader, deep working offset or one-way disc ploughs or one-pass deep tillage systems. Deep ripping before mixing protects equipment, improves mixing and can remove buried obstacles such as rocks and stumps. If your main constraints are subsoil acidity and compaction then deep ripping with topsoil slotting after liming may be adequate. For severe repellence and weed seed burial consider soil inversion with a mouldboard, square or modified one-way plough.

- Deep soil mixing or inversion leaves the soil soft. Often soil will need to be rolled or packed before seeding. Consider how you are going to seed paddock before you ameliorate. Have a plan and get advice from others who have done it before. Do not use deep working points as they increase the risk of sowing too deep and under-seed cultivation is not needed – the soil is soft already.

- Reduce erosion risk by undertaking deep soil mixing when the subsoil is wet and by sowing a cereal cover crop as soon as possible after amelioration.

- Surface crusting can occur after amelioration if soil with higher clay content, including clayey or loamy sand, is brought to the surface, particularly with soil inversion. This can be difficult to manage. Increasing the seeding rate and trying to get the crop up before the soil dries too much can help. Minimise traffic and re-compaction. In subsequent years there is some evidence that additional shallow working in severe crusting areas can improve emergence.

- Herbicide activity can be increased following amelioration which can cause crop damage. Be cautious with pre-emergent products. Use safer chemistry and seek advice from those with prior experience.

- Use baseline soil tests and expected yields to determine likely nutrient requirement. Be aware that additional mineralisation in year 1, and to an extent year 2, will result in more nitrogen being available to the crop. Remain aware of the soil’s water holding capacity and avoid growing too much biomass on soil with low water holding. Subsoil brought to the surface can be low in nutrients and organic matter so starter nutrition can be important.

Risks associated with soil tillage

It is important to understand the characteristics of the soil profile and have a plan to minimise the risk of soil erosion. From Soil Quality: 7 Soil Water Repellence (Davies et al. 2022). Video talent: Tom Edwards, DPIRD; video production: Lomax Media.

Setting up mouldboard ploughs to optimise soil inversion

When carried out effectively, soil inversion almost completely eliminates topsoil water repellence, although in cases of complete or poor inversion, soil retains some repellence. From Soil Quality: 7 Soil Water Repellence (Davies et al. 2022). Video footage: DPIRD; still images and audio talent: Stephen Davies, DPIRD; video editing: Science with Style.

Cost and impact of common management options

Important considerations and conditions for soil management options

When you are not addressing a soil constraint immediately, or if there is a lag time before the treatment is effective (for example liming to treat acidic soil), apply nutrients according to expected potential yield. You can apply nutrients to fix a deficiency, but applying nutrients will not fix a soil constraint that restricts availability or uptake of nutrients.

- The application rates of wetting agents, lime, gypsum and organic matter need to be sufficient and should be based on adequate soil sampling and professional advice.

- Insufficient lime will not fully alleviate soil acidity, reducing return on investment in comparison to sufficient lime applied to ensure acidity does not hinder root growth, particularly if the limed topsoil is subsequently incorporated.

- A higher rate of lime is required if it is to be incorporated into subsurface soil.

- As soil acidification is ongoing, maintenance liming needs to be a regular part of farming practice to maintain the benefits gained from ameliorating soil acidity.

- The rate of lime required to ameliorate water repellence may be higher than the rate required to ameliorate soil acidity and lime is not usually considered as a treatment for water repellence.

- Lime could be used to treat topsoil sodicity providing that the soil is also acidic, however this situation is uncommon. Organic residues, manure or compost imported from off-site may be applied to the soil surface. Retaining stubble, cover crops, green manures, pasture rotations and improvements in net primary productivity also increase inputs of organic matter.

- The benefits from organic matter additions are rate dependent and inputs must be continued indefinitely to maintain benefits. The benefits indicated in the table above assume some incorporation of organic matter.

- The benefits in ameliorating sodicity by gypsum application are contingent on no significant trafficking and compaction occurring. Reapplication is required every 4–5 years. Organic matter contributes to longer-term stability.

It is important to know the chemical composition of your soil profile before undertaking any form of significant soil mixing to avoid inadvertently bringing hostile subsoil to the surface. For example, toxicities associated with alkaline (high pH) subsoil, such as boron or aluminium associated with acidic (low pH) subsoil.

The benefits from ripping, ploughing, spading, or any form of deep tillage are limited to the working depth.

- Acute soil erosion by wind or water is a short-term (1–2 years) risk to crop establishment following any significant soil disturbance and reduction in ground cover. Soil mixing operations, such as mouldboard ploughing, modified one-way ploughing, off-set ploughing and rotary spading result in the highest risk of erosion. It is important to plan to sow a cover crop as soon as possible after significant soil disturbance.

- Before choosing soil disturbance options, check for effective biopores that provide a pathway for roots to grow to adequate depths despite soil constraints. Options such as mouldboard ploughing and rotary spading can destroy biopores.

Conventional ripping in sodic soils to physically break open pathways for root growth is likely to only deliver a one-year benefit.

- The benefits of deep ripping with inclusion plates for treating water repellent soil are contingent upon the topsoil being dry and loose enough to fall down into the slot.

- If subsoil sodicity is being treated by slotting topsoil and gypsum into the subsurface, sodic subsoil must not be brought to the surface during ripping. This process requires operator skill.

- When the mouldboard plough is set up for complete inversion of the soil profile to treat water repellence and bury weed seeds, poor mixing of surface-applied lime is achieved. If the subsurface soil brought to the surface is acidic, additional surface liming may be required so it is important to know your soil pH profile before you start and useful to measure topsoil pH again after inversion. If you have an acidity constraint in addition to water repellence and high weed burden, this option may still be the best.

- When the mouldboard plough is set up for mixing and incorporating surface-applied lime, rapid amelioration of soil acidity is possible. With this option, treatment of water repellence and weed seed burial will be incomplete.

- There is often increased efficacy of herbicides after mouldboard ploughing as a result of lower organic matter and/or higher pH in the surface soil. Triazine, and lupin establishment in particular, is problematic.

- Disc ploughs overcome compaction to the working depth (dependant on the disc size), and may also be used in addition to deep ripping to enable deeper ripping depths. There may also be a benefit from mineralisation of organic matter as a result of the mixing effect of cultivation.

- Mixing can be improved by combining offset disc ploughing with deep ripping.

A modified one-way plough mixes surface-applied lime and buries and/or dilutes non-wetting soil, provided it is set-up appropriately. It will overcome compaction to the working depth.

Spading is unsuitable for soils with rocks or old tree roots. Soils are typically deep ripped prior to spading as it improves the efficiency and effectiveness of the spading process and minimises the likelihood of damage. Spading is very effective in incorporating lime and other ameliorants but can reduce soil structure and biopores and leave soil at risk of erosion.

- Compaction must first be overcome to realise the maximum benefits associated with controlled traffic farming on most soil types, although self-repair can occur on some heavier soils.

- A planning program to align machinery widths to a matched system is required to achieve full benefits.

This practice can destroy the water infiltration points associated with standing stubble that can help with initial wetting up in water repellent soil.

- Any management options that involve soil disturbance will reduce soil organic matter in the short term, but if net primary productivity is increased and maintained, soil organic matter can build up to higher levels in the long term.

- Increased soil organic matter can make water repellence worse as it increases the concentration of hydrophobic (water repellent) organic compounds in the soil.

- Deep working just means sowing with deeper knife points.

- Deep working may be most beneficial in marginal country where you only want small increases in rooting depth, without alleviating significant compaction. If the remaining soil is compacted root growth will be slow, which can prevent crops producing too much biomass. This may help to prevent premature haying-off of crops due to insufficient water later in the season.

The results in water repellent soil are variable, depending on how soil type, soil moisture content and location in the profile, speed of seeding and the design of seeding implement impact on movement of repellent topsoil and seed placement within the furrow.

- Standard soil tests plus PBI (phosphorus buffering index), clay percentage and boron should be known prior to claying. Appropriate application rates are essential to achieve benefits and depend on the nature of the soil being treated and the composition of the clay.

- Some clays can add nutrients, especially potassium.

- Soil acidity amelioration is limited and contingent on the clay being alkaline.

- The option of clay delving depends on being able to bring up sufficient clay.

- The additional benefits of clay delving for overcoming compaction depend on tine spacing being close enough.

- Clay spreading requires some incorporation of clay into the topsoil while delving requires smoothing of the surface prior to sowing.

Page references and acknowledgements

Material on this page adapted from:

- Murphy D, Leopold M, van Gool D, Hoyle FC and Stockdale E (2017). Soil Quality: 1 Constraints to Plant Production. SoilsWest, Perth, Western Australia. [Access]

- Pluske W, Boggs G and Leopold M (2018). Soil Quality: 2 Integrated Soil Management. SoilsWest, Perth, Western Australia. [Access]

- Parker W, Isbister B, Hoyle FC and Leopold M (2021). Soil Quality: 6 Soil Compaction. SoilsWest, Perth, Western Australia. [Access]

- Davies S, Fisher J, Roper M and Murphy D (2022). Soil Quality: 7 Soil Water Repellence. SoilsWest, Perth, Western Australia. [Access]

- Barrett-Lennard EG, Hall D, Parker W and Munir R (2022). Soil Quality: 8 Sodic and Alkaline Soil. SoilsWest, Perth, Western Australia. [Access]

Last updated July 2024.